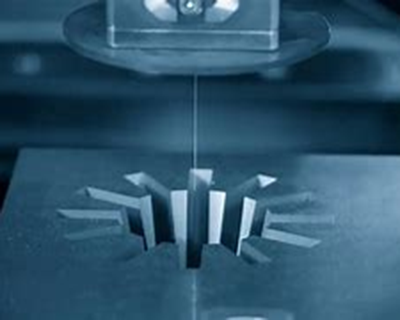

5 axis CNC machining is an advanced manufacturing process that utilizes five axes of motion to cut and shape materials. This technology is an improvement over the traditional 3 axis machining process, as it allows for greater flexibility and precision in machining complex parts. The additional two axes (A and B) provide more freedom of movement to the cutting tool, which can approach the material from various angles, allowing for more intricate and precise cuts.

There are several advantages to using 5 axis CNC machining over traditional 3 axis machining. Here are some of the most significant advantages:

5 axis CNC machining can improve accuracy and accuracy

One of the most significant advantages of 5 axis CNC service is its ability to produce highly precise and accurate parts. The additional two axes allow the cutting tool to approach the material from different angles, resulting in more intricate and precise cuts. This increased precision and accuracy is essential in industries such as aerospace and medical device manufacturing, where even the slightest deviation from specifications can have significant consequences.

5 axis CNC machining can reduce setup time and improve efficiency

5 axis CNC machines are equipped with advanced software that allows for faster set-up times and increased efficiency. The software can automatically adjust the cutting tool's position and orientation, eliminating the need for manual adjustments. This reduces the time required for set-up and increases the overall efficiency of the machining process.

5 axis CNC machining has greater flexibility and versatility

5 axis CNC machines offer greater flexibility and versatility than traditional 3 axis machines. The additional two axes allow for more freedom of movement, enabling the cutting tool to approach the material from different angles. This flexibility and versatility make 5 axis CNC machines ideal for machining complex and irregularly shaped parts.

5 axis CNC machining to reduce material waste

As one of the precision tool making, 5 axis CNC machining allows for more precise cuts, which can significantly reduce material waste. This is particularly important in industries such as aerospace and automotive, where materials such as titanium and carbon fiber can be expensive.

5 axis CNC machining reduces labor costs

5 axis CNC machines require less labor than traditional 3 axis machines. The advanced software allows for faster set-up times and increased efficiency, which can reduce the number of operators required to run the machine. This can result in significant cost savings for manufacturers.

- Medical Marvels: Urethane Casting for Prosthetics and OrthopedicsNovember 23, 2023In the ever-evolving world of medical technology, new advancements are constantly being made to improve the lives of patients. One such innovation that has revolutionized the field of prosthetics and ...view

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view

- Custom Prototyping Services: The Key Bridge of Product DevelopmentJune 14, 2024In the journey of product development, prototyping occupies a crucial position. It is not only a bridge between design and actual manufacturing but also the first step in turning creativity into reali...view