In the ever-evolving world of medical technology, new advancements are constantly being made to improve the lives of patients. One such innovation that has revolutionized the field of prosthetics and orthopedics is urethane casting. This cutting-edge cast urethane service is transforming the way prosthetic limbs and orthopedic devices are manufactured, offering patients enhanced comfort and functionality.

What is Urethane Casting?

Urethane casting is a process that involves the creation of unique molds for prosthetic limbs and orthopedic devices using a specialized urethane material. This material is known for its flexibility, durability, and bio-compatibility, making it an ideal choice for medical applications. With urethane casting, medical professionals can produce custom-designed prosthetics and orthopedic devices that perfectly fit an individual's unique anatomy.

Benefits of Urethane Casting for Prosthetics

The use of urethane casting in the production of prosthetic limbs offers several significant benefits for patients. Firstly, urethane is a lightweight material that provides comfort and ease of movement. Unlike traditional prosthetics made from heavier materials such as metal, urethane prosthetics allow users to experience a more natural range of motion.

Additionally, urethane casting allows for the creation of personalized prosthetics that are tailored to a patient's specific needs. Through the use of 3D scanning and modeling technology, medical professionals can capture the precise measurements and contours of an individual's limb, ensuring a perfect fit. This level of customization results in increased comfort, improved functionality, and better overall quality of life for prosthetic users.

Advantages of Urethane Casting for Orthopedic Devices

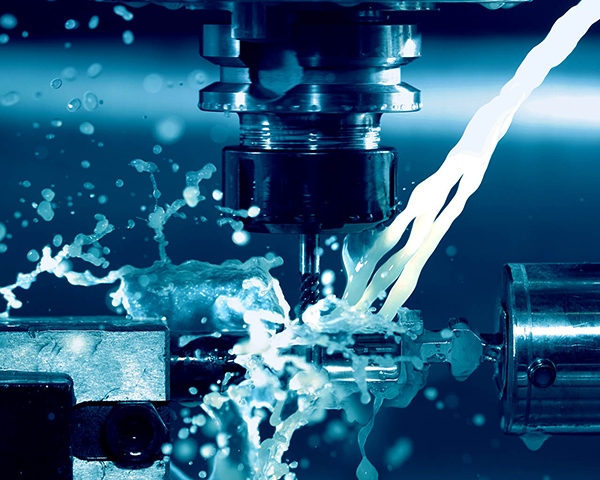

As a common precision prototyping machining, urethane casting is not limited to prosthetics; it also offers significant advantages in the manufacturing of orthopedic devices. Whether it's a custom brace, splint, or support device, urethane casting allows for the creation of orthopedic devices that closely match the patient's anatomical structure.

One of the major advantages of urethane casting for orthopedics is its ability to provide targeted support. By capturing the unique shape and measurements of a patient's body, orthopedic devices can be designed to distribute pressure and provide support precisely where it is needed. This results in improved comfort, enhanced mobility, and better injury recovery for patients.

The Future of Urethane Casting

As technology continues to advance, so too will the capabilities of urethane casting for prosthetics and orthopedics in prototype manufacturing companies. The use of 3D printing in urethane casting is on the horizon, which will further streamline the manufacturing process and allow for even more intricate and complex designs.

Furthermore, research and development in urethane materials are ongoing. Scientists are continually optimizing the properties of urethane to improve its durability, flexibility, and bio-compatibility. These advancements will enable medical professionals to create prosthetic limbs and orthopedic devices that are even more comfortable, functional, and long-lasting.

Urethane casting has emerged as a medical marvel, transforming the landscape of prosthetics and orthopedics. With its ability to create custom-made devices that perfectly fit the unique anatomy of each individual, urethane casting offers unprecedented comfort and functionality. As technology continues to evolve, the future of urethane casting holds exciting possibilities for enhancing the lives of patients. With ongoing research and development, this innovative process is set to revolutionize the medical field, providing advanced solutions for individuals in need of prosthetics and orthopedic support.

- Aerospace Advancements: Breaking Barriers with Precision Prototype MachiningJanuary 5, 2024As we continue to explore the boundless possibilities of space travel and aerospace engineering, one crucial element stands at the forefront of innovation – precision prototype machining. From pushin...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- Speeding Up Style: Custom Rapid Prototyping in Fashion DesignNovember 23, 2023Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In rece...view

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- The Future of Manufacturing: Urethane Casting Services in a Dynamic IndustryJanuary 5, 2024In the ever-evolving landscape of manufacturing, where precision, flexibility, and speed are paramount, the future is being shaped by innovative technologies like urethane casting services. This dynam...view

- What Are the Advantages of 5 Axis CNC?September 19, 20235 axis CNC machining is an advanced manufacturing process that utilizes five axes of motion to cut and shape materials. This technology is an improvement over the traditional 3 axis machining process,...view