Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely applied in important industries such as automotive, home appliances, transportation, and defense. Custom prototyping services, while improving prototype quality, ensuring final product quality, and meeting the ever-changing market demands, will also promote the overall competitiveness of the entire prototyping manufacturing industry.

The Necessity of Custom Prototyping Services

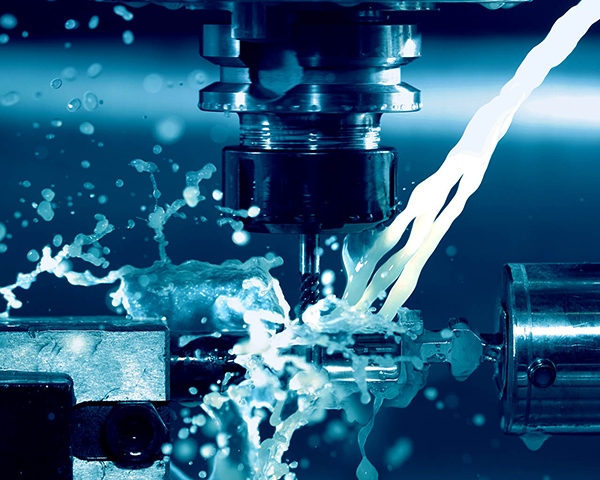

Each mold is composed of numerous components, and the quality of these components directly affects the overall quality of the mold. Precision machining technology is the foundation for ensuring the quality and performance of these components. This includes grinding, deburring& polishing, cleaning, and surface treatment. The core characteristic of precision molds is their high precision in operation, which requires more advanced equipment and technology during manufacturing and processing. Custom prototyping services ensure that molds can meet the stringent accuracy and quality requirements during production.

Precision Grinding Technology Solutions

In the process of custom prototyping services, grinding work accounts for about 25% to 45% of the total manufacturing hours. The choice of equipment and processes is particularly important; otherwise, issues like grinding cracks, grinding marks, and grinding stress can arise, which not only damage the surface quality of the mold but also potentially shorten its lifespan. CNC milling is a highly automated processing technology. By precisely controlling the movement trajectory of the milling cutter through a computer numerical control system, it meets the stringent requirements for high precision and complex shape processing of mold cavities.

Accurately Grasp Market Demands

During the product development process, changes in market demand often have a significant impact on the product. Through custom prototyping services, prototype manufacturing companies can market-test the molds before actual production and collect user feedback. This method of accurately grasping market demands helps companies timely adjust product strategies, meet market needs, and enhance product competitiveness.

Optimizing Production Process Flow

In the product development process, optimizing the production process flow is crucial for improving production efficiency and reducing costs. Through custom prototyping services, companies can test the production processes of prototype products before actual production, identify bottlenecks and issues in the production process, and optimize and improve them. This way of optimizing the production process flow can save a significant amount of time and cost for companies, improving the efficiency and quality of product development.

In order to maintain a leading position in the fierce global market, the mold industry also needs to actively introduce high-end equipment and technologies, including precision machine tools and robotics. Custom prototyping services can create complex mold cavity structures that are difficult to achieve with traditional processes, promoting industry transformation and upgrading, and better meeting market demands.

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Gaming Gadgets Galore: How Urethane Casting Services Shape Interactive ExperiencesJanuary 5, 2024In the dynamic world of gaming, where innovation and immersive experiences are driving forces, the role of urethane casting services emerges as a crucial element in the development of cutting-edge gam...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view

- Custom Prototype Manufacturing in ConstructionMarch 19, 2024In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Fathom Precision stands out in the field of custom prototype manufacturing in const...view

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view