Our precision prototyping machining service is making customer's design concept into practical, functional, and testable products with fast lead time and competitive prototyping prices. Our prototype machining manufacturing development is capable of manufacturing a wide range of custom prototype manufacturing products including, Urethane Casting, 3D printing, prototype CNC machining, and Metal Forming for the medical, automotive, toys, and industrial sectors from final prototyping service design to real products for performance and mechanical test as well as ergonomics evaluation. This would offer the customer touching and feeling of the actual parts in a short lead time at minimal investment.

You are welcome to provide the CAD model in different format such as Solidwork, Parasolid, STEP, ProE, IGS with material selection and part specification.

Review and study the part design intensively then provide competitive custom rapid prototyping prices and our manufacturing comments to the customer.

Once the custom prototype manufacturing completed, dimensional inspection will be performed and First Article Inspection report will be provided to customer to review and confirm shipment.

The timeline for custom prototype manufacturing can vary greatly depending on the complexity of the design, the materials used, and the manufacturing process. It can take anywhere from a few days to several months. For simple prototypes using common materials, it might take a few days to a week. For more complex prototypes or those requiring special materials or manufacturing processes, it could take several weeks to a few months. It's always best to consult with the manufacturer for an accurate timeline.

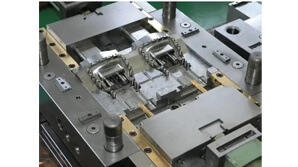

Prototype machining services involve the creation of a physical model or sample of a product design using various machining processes. This can include processes like milling, turning, drilling, or cutting, among others. The purpose of these services is to create a tangible representation of a design concept that can be tested and evaluated before moving into full-scale production. This allows designers and engineers to identify and correct any potential issues or flaws in the design, ultimately saving time and money in the long run. These services can work with a wide range of materials, including metals, plastics, and more.

Custom prototyping is a game-changer in applied industries, seamlessly bridging concepts to real-world solutions. This dynamic process, integral to manufacturing, healthcare, and technology, offers a rapid and cost-effective approach to innovation. Let's explore how custom prototyping is shaping tomorrow's automotive prototyping solutions across diverse industries.

Key Applications:

Manufacturing and Engineering:

Streamlining product development and optimizing tooling and mold designs.

Healthcare Advances:

Driving innovation in medical device development, bioprinting, and tissue engineering.

Technological Breakthroughs:

Revolutionizing electronics, circuit design, robotics, and automation.

Aerospace Advancements:

Enhancing the development and testing of aircraft components, ensuring precision and safety.

Automotive Innovation:

Optimizing vehicle design, testing components, and improving overall automotive efficiency.

Scale Model Production:

Serving as the backbone for creating precise and scaled models, crucial for design visualization.

Consumer Product Development:

Enabling the rapid iteration and refinement of consumer goods, ensuring market-ready products.