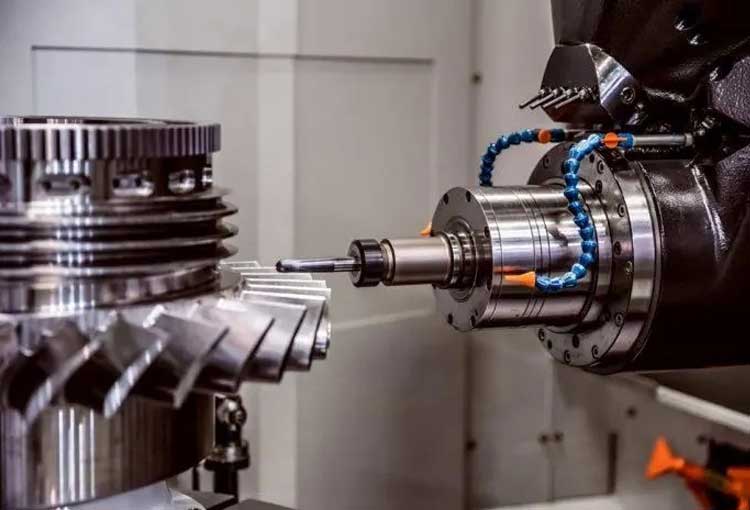

Fathom Precision CNC machining company provides with wide range of OEM precision prototyping CNC machining including 3-Axis, 4-Axis and 5-Axis CNC machines, CNC lathes for precision turning, precise wire & EDM cutting, 2D optical projector, CMM measuring machines, height guage, micrometer, roughness test, and impact tester those offering extensive precision CNC machining manufacturing with quality control capability.

The rapid prototype machined parts and products cover such fields as mechanical, robots, automotive, electronics, medical, and communications with fast turnover.

As a leading prototype manufacturing company, our CNC manufacturing services Include different types of materials such as plastic, brass, copper, aluminum, stainless steel, and titanium alloys.

Offering all types of specified surface-finish management to fulfill customer custom CNC machining service needs such as anodizing, electroplating, spraying, polishing and texturing.

Distinguished for machining varities of precise and complex structural parts from small to large metal and plastic components or products.

Can minimize CNC machining material wastage because of custom precision machining manufacturing there will be fewer damaged parts to discard

Producing more precision CNC machining and identical parts

The inherent speed and efficiency of production are capable of producing products much more quickly and efficiently than traditional prototype CNC machining methods.

Custom rapid prototyping CNC machining components/Products are created under computer numerical control and are simpler to assemble so precise and consistent parts produced

Automating the OEM precision cnc machining process can eliminate hazards associated with manual machining.

Less electricity than older processes, thereby reducing energy consumption.

Economical, efficient, and precision machining and manufacturing process of parts and products.