In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its ability to bring ideas to life, prototype machining is revolutionizing vehicle design, enabling manufacturers to push boundaries and create groundbreaking concepts. In this blog post, we will explore how prototype machining has become a game-changer in the automotive industry, highlighting its significance in the process of designing and manufacturing vehicles.

A Game-Changer in Automotive Industry Evolution

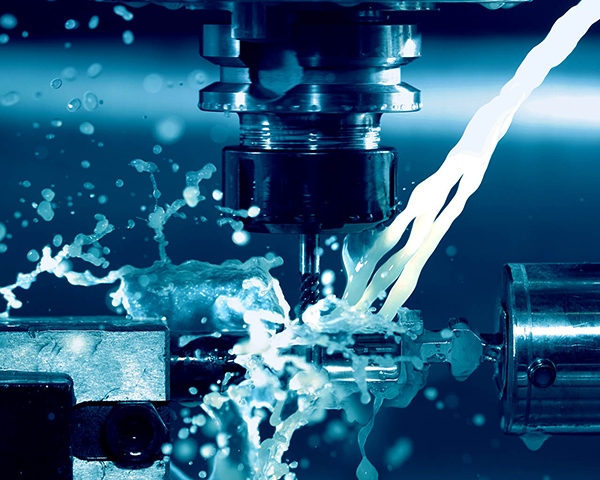

The traditional approach to vehicle design followed a time-consuming and costly route, involving manual mold making and subsequent testing. However, thanks to the advent of prototype machining, manufacturers now have a faster and more efficient alternative. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, engineers can create a virtual blueprint of a vehicle component or design concept. From there, a rapid prototype can be produced, allowing for thorough testing and evaluation.

Prototype machining accelerates the overall design process, reducing time and resources required for multiple iterations of product development. This streamlined approach brings tremendous benefits to the automotive industry, enabling manufacturers to optimize their designs and reduce the time it takes for vehicles to reach the market.

The Power of Prototype Machining in Vehicle Design and Manufacturing

Prototype machining is an essential tool for automotive design and manufacturing, as it allows manufacturers to verify their concepts with real-life samples. By creating physical prototypes, engineers can perform in-depth testing, evaluating the functional aspects, durability, and overall performance of the vehicle components. Any required modifications or improvements can be identified and implemented efficiently, greatly minimizing the risks and costs associated with design flaws.

Additionally, prototype machining opens up avenues for innovation and creativity. By swiftly bringing design ideas to reality, manufacturers can explore novel concepts and experiment with unconventional features. This freedom to innovate gives birth to groundbreaking automotive designs that captivate the market and propel the industry forward.

Moreover, prototype machining plays a pivotal role in the manufacturing process. It allows manufacturers to test the feasibility of mass production, assess manufacturing tolerances, and fine-tune assembly processes. This ensures that once the final design is approved, the vehicle can be produced efficiently, meeting the highest quality standards.

In conclusion, prototype machining is redefining vehicle design and manufacturing in the automotive industry. With its ability to accelerate the design process and enable rapid testing and evaluation, it ensures that innovative concepts become a reality. By embracing prototype machining, manufacturers can push boundaries, optimize designs, and create vehicles that captivate the market. As the automotive industry continues to evolve, prototype machining plays a crucial role in shaping the future of vehicle design and technology.

- What Are The Characteristics Of Precision CNC MachiningFebruary 27, 2023First, precision CNC machining process is concentratedCNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, th...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view

- Speeding Up Style: Custom Rapid Prototyping in Fashion DesignNovember 23, 2023Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In rece...view

- Medical Marvels: Urethane Casting for Prosthetics and OrthopedicsNovember 23, 2023In the ever-evolving world of medical technology, new advancements are constantly being made to improve the lives of patients. One such innovation that has revolutionized the field of prosthetics and ...view