In the world of rapid prototyping and low-volume production, urethane casting has emerged as a versatile and cost-effective method. Urethane casting services offer a wide array of benefits that can revolutionize the way products are developed and manufactured. In this blog, we'll dive deep into this fascinating technology to understand the advantages it brings to the table.

What is Urethane Casting?

Urethane casting service, also known as polyurethane casting, is a manufacturing process that involves using silicone molds to replicate detailed, high-quality parts. This technique is particularly well-suited for creating prototypes and small to medium-production runs.

Benefits of Urethane Casting

Let's explore the numerous advantages that urethane casting services offer:

Cost-Effective Prototyping

Urethane casting is a cost-effective alternative to traditional injection molding for prototyping. It allows designers and engineers to create multiple prototypes quickly and at a fraction of the cost, helping to validate their designs before investing in more expensive production tooling.

Fast Turnaround

The process of urethane casting is remarkably swift, with parts ready in days rather than weeks. This rapid turnaround time is ideal for meeting tight project deadlines and getting products to market faster.

Wide Material Selection

Urethane casting offers a wide range of material options, allowing for the simulation of the desired mechanical properties, textures, and colors of the final product. This versatility of urethane casting materials is a significant advantage for product development and design testing.

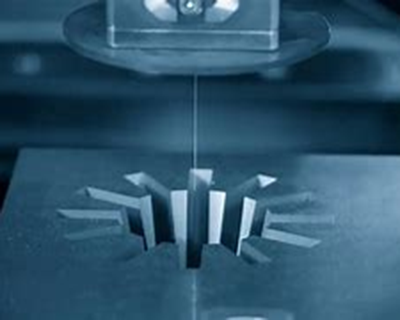

Complex Geometries and Fine Details

Urethane casting excels at replicating intricate and complex part geometries, ensuring that every detail is captured. This is particularly valuable for components with challenging designs or high aesthetic requirements.

Low-Volume Production Solutions

Urethane casting is not limited to prototyping; it's also suitable for low-volume production. It enables the cost-effective creation of small to medium production runs, providing an economical solution for companies needing custom parts without the expense of large-scale manufacturing processes.

Applications of Urethane Casting

Urethane casting services have found applications in various industries:

Automotive: Creating concept car components for design validation.

Medical Devices: Developing prototypes of medical instruments and devices.

Consumer Electronics: Designing and testing electronic device casings.

Aerospace: Producing custom aerospace components for research and development.

Industrial Equipment: Developing parts for machinery and equipment.

Urethane casting services are a game-changer in the world of rapid prototyping and low-volume production. With their cost-effectiveness, speed, material versatility, ability to capture complex details, and suitability for small production runs, they offer a range of benefits that can help businesses bring innovative products to market efficiently. As technology continues to advance, urethane casting services are becoming an integral part of product development and manufacturing, unlocking new possibilities for designers, engineers, and manufacturers alike.

- Sports Equipment Redefined: Urethane Casting Services in Athletic Gear ManufacturingJanuary 5, 2024In the ever-evolving world of sports gear manufacturing, innovation is key to staying ahead of the game. As athletes continually strive to push their limits, manufacturers must find ways to deliver eq...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- Custom Prototype Manufacturing in ConstructionMarch 19, 2024In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Fathom Precision stands out in the field of custom prototype manufacturing in const...view

- The Role of Prototyping ServicesMarch 19, 2024Prototyping services play a pivotal role in modern manufacturing. It is not only a bridge between product design and production, but also a key force to promote product innovation and optimization. Fa...view