The world of manufacturing and rapid prototyping has seen significant advancements in recent years. While 3D printing has gained immense popularity for creating prototypes and functional parts, there's another precision prototyping method that deserves its share of the spotlight—Precision Prototyping Machining. In this blog, we will take a closer look at this cutting-edge technique and why it's gaining traction in the manufacturing industry.

Understanding Precision Prototyping Machining

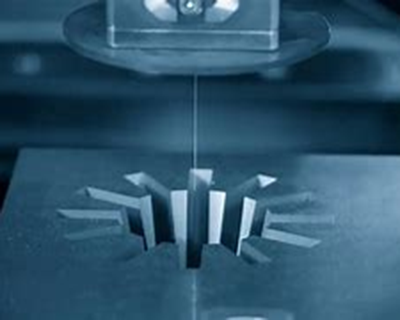

Precision Prototyping Machining is a subtractive manufacturing process that involves shaping materials to create a final product. Unlike 3D printing, which adds material layer by layer, machining removes material from a solid block to achieve the desired shape. This method is particularly well-suited for producing high-precision and complex components with tight tolerances.

The Advantages of Precision Prototyping Machining

Unmatched Precision and Accuracy

One of the key advantages of precision prototyping machining is its exceptional precision. It can achieve tolerances as tight as a few microns, making it ideal for applications where accuracy is paramount. Whether you're working on aerospace components or intricate medical devices, machining can meet your precision requirements.

2Wide Range of Materials

Unlike 3D printing, which is often limited to specific materials, precision prototyping machining can work with a wide variety of materials, including metals, plastics, ceramics, and composites. This versatility makes it a go-to choice for a broad spectrum of industries.

Superior Surface Finish

Machining can produce parts with a superior surface finish, such as CNC machining small parts, which is crucial for components that require a polished, high-quality appearance. This is especially important in industries like automotive, where aesthetics play a significant role.

Cost-Effective for Small to Medium Production Runs

While 3D printing excels in rapid prototyping and customization, machining becomes more cost-effective for small to medium production runs. The time and materials saved in this process make it an attractive choice for manufacturers looking to scale their operations.

Applications of Precision Prototyping Machining

Precision prototyping machining has found applications in various industries, including:

Aerospace: Crafting precision components for aircraft and spacecraft.

Medical: Manufacturing intricate medical devices and implants.

Automotive: Producing high-precision automotive parts.

Electronics: Creating complex components for electronics and semiconductors.

Defense: Developing critical defense and military equipment.

Tooling: Crafting molds, dies, and tooling for various manufacturing processes.

While 3D printing has revolutionized rapid prototyping and customization, precision prototyping machining is carving out its niche as the go-to method for achieving exceptional precision, working with a wide range of materials, delivering superior surface finishes, and being cost-effective for small to medium production runs. Manufacturers are increasingly recognizing the value of precision machining in their quest for high-quality, precise, and functional parts. As technology continues to evolve, precision prototyping machining is set to play a pivotal role in the future of manufacturing.

- Custom Prototyping Services: The Key Bridge of Product DevelopmentJune 14, 2024In the journey of product development, prototyping occupies a crucial position. It is not only a bridge between design and actual manufacturing but also the first step in turning creativity into reali...view

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view

- What is the Tolerance of a 5 Axis CNC Machine?September 19, 2023What is 5 Axis CNC Machining?5 axis CNC machining is a type of computer-controlled machining that uses five axes of motion to cut and shape materials. The five axes allow for greater flexibility and p...view