Introduction to Pressure Casting

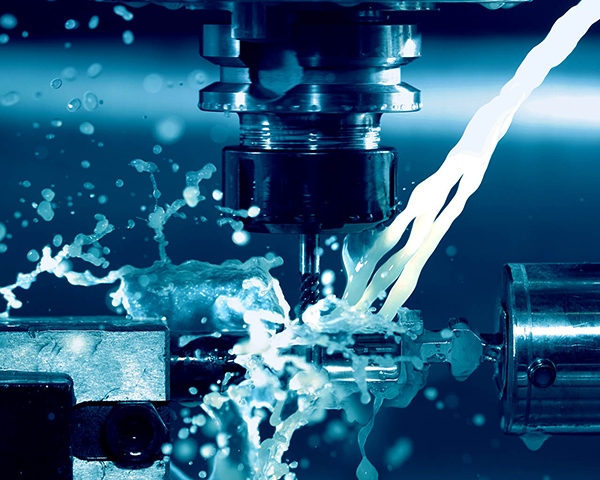

Pressure casting is a casting method in which molten or semi-molten metal is pressed into the metal casting mold at high speed and crystallized under pressure, referred to as die casting.

Advantages Of Pressure Casting

1) High productivity, easy-to-achieve mechanization, and automation, can produce thin-walled castings with complex shapes. The minimum wall thickness of die-casting zinc alloy is only 0.3mm, the minimum wall thickness of die-casting aluminum alloy is about 0.5mm, and the minimum cast out hole diameter is 0.7mm.

2) High dimensional accuracy of castings, small surface roughness value. Die casting size tolerance grade up to CT3 ~ CT6, the surface roughness is generally Ra0.8 ~ 3.2μm.

3) Pressure casting parts can be embedded in the casting silicone parts, not only to save valuable materials and machining hours but also to replace the assembly process of the parts, eliminate the assembly process, and simplify the manufacturing process.

Application Of Pressure Casting

Due to the advantages of pressure casting, it is widely used, mainly in mass production of non-ferrous alloy castings. Pressure die casting applications are the most automobile, and tractor manufacturing, followed by instrument manufacturing and electronic instrument industry, again for agricultural machinery, defense industry, computers, medical equipment, and other manufacturing industries. The parts produced by the die-casting method are the engine cylinder block, cylinder head, transmission case, engine cover, instrumentation and camera shell and bracket, pipe fittings, gears, etc. In recent years, high technology has been applied to pressure casting. Such as the use of a three-stage pressure injection mechanism to control the pressure, injection speed, and gas in the mold. Development of special pressure casting processes (such as vacuum die-casting, directional pressure casting, oxygen die-casting, etc.) and the application of computer control technology to effectively remove the pores, improve the density of the casting while developing new mold materials and heat treatment of new technology to extend the life of the die, so that ferrous metal die-casting has made some progress.

- The Role of Custom Rapid Prototyping in Product DevelopmentMarch 19, 2024With the increasingly fierce competition in the market, the speed and quality of product development have become the key factors for the success of enterprises. Among them, custom rapid prototyping pl...view

- Custom Prototyping Services: The Key Bridge of Product DevelopmentJune 14, 2024In the journey of product development, prototyping occupies a crucial position. It is not only a bridge between design and actual manufacturing but also the first step in turning creativity into reali...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view

- Exploring the Capabilities of 5 Axis CNC MachiningSeptember 1, 20235 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of p...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view