In today's digital age, microelectronics play an increasingly significant role in shaping our technological landscape. From smartphones and laptops to medical devices and self-driving cars, these tiny marvels enable us to live in a connected, high-tech world. But have you ever wondered how these microelectronics are produced with such precision? Enter high precision tools – the unsung heroes that allow us to create the wonders of modern technology.

High precision tools are vital in the world of semiconductor manufacturing, where nanometer-scale features dictate the performance of microchips. These tools ensure that every step of the manufacturing process, from design to final inspection, is executed with unparalleled accuracy and quality. In this blog, we will explore the importance of high precision tools in semiconductor manufacturing and delve into some of the incredible technology behind these tools.

The Role of High Precision Tools in Semiconductor Manufacturing

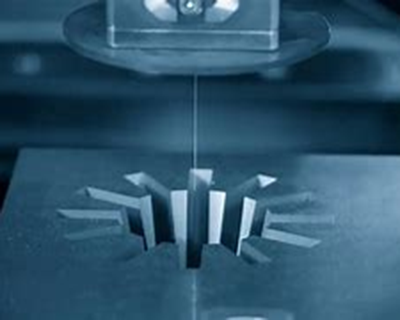

Semiconductor manufacturing involves a complex series of processes, including lithography, etching, deposition, and packaging. At every stage, high precision tools are indispensable in ensuring that the dimensions and alignments of critical components are precise to the nanometer level. Even a tiny deviation from the specifications can significantly affect the overall performance and reliability of the microchip.

For instance, lithography, which involves transferring circuit patterns onto a silicon wafer, relies heavily on high precision tools such as photolithographic steppers. These machines utilize advanced optics, laser systems, and computer-controlled positioning systems to achieve extraordinary precision in patterning the chip's features. Without the accuracy provided by such tools, the miniaturization and complexity of modern microelectronics would not be possible.

Cutting-Edge Technology Behind High Precision Tools

High precision tools are a result of continuous innovation and technological advancements. In recent years, the development of extreme ultraviolet (EUV) lithography has revolutionized semiconductor manufacturing. EUV lithography utilizes a wavelength of light at 13.5 nanometers, allowing for even finer details and reducing process complexity. This breakthrough technology enables the fabrication of more densely packed transistors and enhances chip performance while reducing power consumption.

Another example of cutting-edge technology is the advent of atomic layer deposition (ALD) for depositing thin films with atomic-level control. ALD ensures precise thickness and uniformity, which are critical for the performance and reliability of modern microchips. The combination of high-precision tools like ALD and EUV lithography has pushed the boundaries of semiconductor manufacturing, enabling the production of faster, more efficient, and more powerful microelectronics.

Advancements in High Precision Tools and their Impact on Semiconductor Manufacturing

As new challenges emerge in semiconductor manufacturing, the demand for high precision tools continues to grow. The continuous push for miniaturization, increased functionality, and higher device speeds requires more sophisticated tools and techniques. Manufacturers are investing in research and development to develop tools that can meet these ever-increasing demands.

With advancements in machine learning and artificial intelligence, high precision tools are becoming smarter and more autonomous. These tools can self-optimize processes, detect and correct errors in real-time, and provide valuable feedback for process improvements. Additionally, the integration of high precision tools with advanced metrology techniques enables comprehensive inspection and characterization of microchips, ensuring compliance with stringent quality standards.

In conclusion, high precision tools are the unsung heroes that enable the production of microelectronics that power our modern world. From lithography systems and atomic layer deposition to cutting-edge advancements like EUV lithography, these tools push the boundaries of what is possible in semiconductor manufacturing. As technology continues to advance, it is certain that high precision tools will play a crucial role in shaping the future of microelectronics, enabling even more astonishing marvels.

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- How Is Prototyping Used in the Automotive Industry?July 22, 2023Automotive rapid prototyping is an essential process used in the automotive industry to develop new vehicles and components. Prototyping allows designers and engineers to test and refine their ideas b...view